135 Years of Expertise

Hot & Cold Rolling Mill Equipment

Ferrous and non-ferrous producers around the globe depend on Butech Bliss because we offer some of the most experienced engineering minds anywhere. Butech Bliss offers both trouble-shooting and engineering expertise.

Competitors cannot touch the market niche Butech Bliss has developed in providing tailor-made solutions for our rolling mill partners. Your customers are demanding more because their customers are demanding higher strength steels and specialty alloys for everything from the automotive to emerging energy markets.

Butech Bliss has built mills for just about every application over its 135 years span. With this breadth of experience in ferrous and non-ferrous rolling mills, we stand ready to perform services for:

- Hot Rolling Mill Equipment

- Single-Stand Cold Reduction Mills

- Multi-Stand Cold Reduction Mills

- Temper or Skin Pass Mills (in-line or reel to reel)

- All auxiliary coil handling and mill threading equipment

- All auxiliary support systems

Features That Set Us Apart

Included in Typical Mill Modernization

- Hot Rolling Mill Equipment

- Single-Stand Cold Reduction Mills

- Multi-Stand Cold Reduction Mills

- Temper or Skin Pass Mills (in-line or reel to reel)

- All auxiliary coil handling and mill threading equipment

- All auxiliary support systems

Rolling Mill Automation Services

- Roll gap, gauge and elongation control

- Work roll bending control

- Sequencing

- Plant-wide interfacing

- Data acquisition and statistical analysis

Replacement Parts

Butech Bliss offers a variety of material handling solutions, including scissor lift low profile transfer cars, L-shaped coil cars, pit mounted coil cars, and cross bay transfer cars. These transfer cars come with multiple lift deck configurations and can be operated via remote control. Our material handling offerings also include stacker lift tables, runout conveyors for sheet and plate, coil tilters, pack turnover devices, and custom-designed equipment tailored to unique applications.

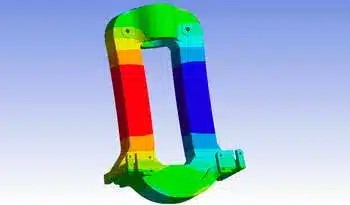

Finite Element Analysis

Butech Bliss engineers are well versed in Finite Element Analysis; a powerful tool used for solving complex stress situations. This assures that our team brings a complete engineered solution to our customers.

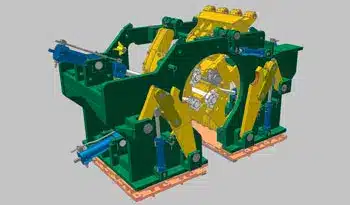

3D Solid Modeling

3D solid modeling is yet another tool being used by our engineering team. This progressive technology permits our engineers to create three dimensional virtual models and apply simulated motion to predict real world performance.

Engineering Studies

Hundreds of engineering studies have been completed in recent years by our engineers to the great benefit of our customers. Studies range from basic layout work to detailed engineering development. These engineering studies are pivotal to envisioning project feasibility and return on investment.

Get Started Today

Request a Free Quote for Your Custom Solution

Our team is ready to design, build, and deliver solutions that meet your exact specifications. Share your project details, and we’ll provide a customized quote to help you take the next step.

Trusted Across Industries

Solutions Tailored to Your Specific Needs

Whether you’re in automotive, aerospace, construction, or steel production, Butech Bliss provides equipment designed to meet the unique demands of your sector. Our engineering expertise ensures optimized performance, every time.

Question?

Contact Us

Send us a message to learn more about our equipment or services.

Our team can determine the best solution based on your requirements and offer a free quote!

Phone: 330-337-0000

Toll Free: 888-285-6433

Request a Quote

550 S. Ellsworth Ave.

Salem, Ohio 44460